Hello everybody! So I have already unpacked the environmental impact of bamboo, and we have already talked about the pros and cons of everything from bamboo as a building material – to those zero-waste aesthetic bamboo cutlery sets we see everywhere. In the last video about bamboo, we uncovered how bamboo is naturally a pest-repellant, how it can grow in dry soils and on slopes where trees cannot grow, and how it actually benefits the soil. We have talked about how bamboo is a type of grass and not a tree and how the fast-growing types of bamboo used for modern consumption are not the same types of bamboo as our sweetest (but no-survival-skills-having) panda exclusively eats. However, as we also talked about last, even though there are so many good things to be said about bamboo, the industry is still rather untransparent, or at least it can be. If you are interested in knowing more, check out that video.

Today, we are going to talk about a specific type of bamboo product that lots of you have requested – and that is bamboo clothing. So let’s take a look at how bamboo clothing is made and while we’re at it, let’s take a look at some of the claims made about the benefits of bamboo clothing.

also check out: ECO CERTIFICATION GUIDE pt I // what are they telling you – and what AREN’T they

Production

How is bamboo clothing made? Now when I was younger, my brother and I would play in the family garden, and in the back there grew these huge bushes of bamboo. During the summer we would cut one off each and pretend they were swords. I remember the intense pain of being hit over the knee with this bamboo stick. The moral of the story: you should never engage in a pain contest with your siblings, and that bamboo is a pretty rough and hard material. So exactly how can you make it a soft and comfortable garment? In bamboo textile production there are two methods of doing that.

also check out: THE IMPACT OF FAST FASHION // watch this before buying new clothes

The first one is mechanical. Here you crush the bamboo into a paste, and with natural enzymes, you break down the hard plant fiber, then you comb through the fibers and spin it into yarn. This type of fabric is typically referred to as bamboo linen. Although the method is not always 100% sustainable, there is definitely potential for innovation here, and definitely the more sustainable of the two options. However, it requires a lot of hard labor, so it is expensive, and the fabrics will not come out soft or smooth like cotton or silk

also check out: 5 TYPES OF GREENWASHING // reacting to greenwashing ads and products clothes

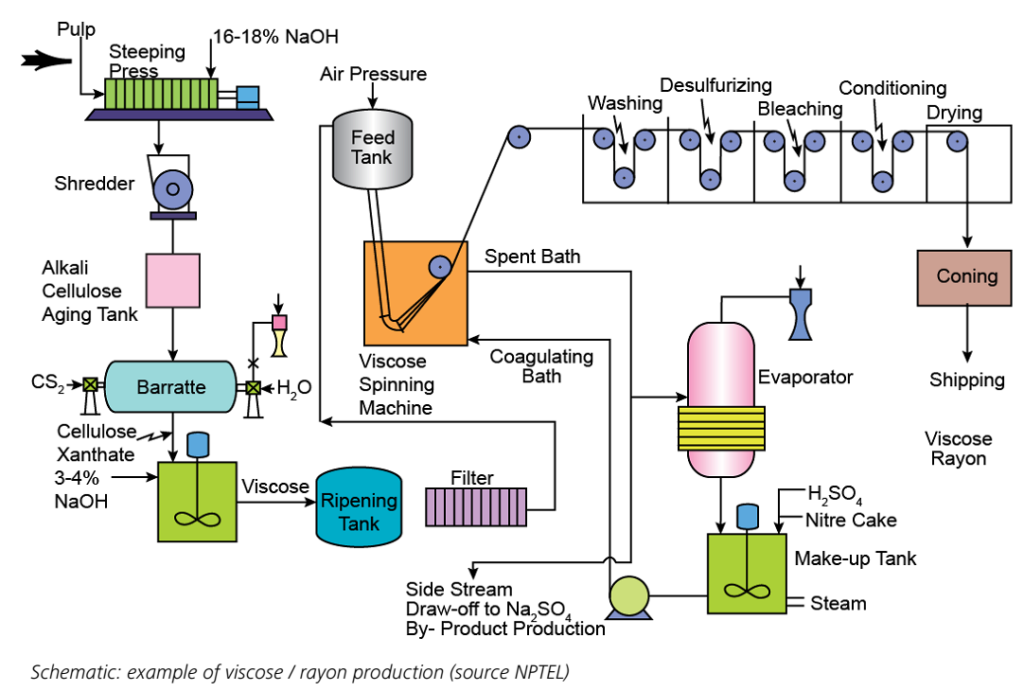

The other method is chemical (and I guess you can already guess where I am going with this). Here the bamboo plant is “cooked” in a mix of chemical solvents, like sodium hydroxide, lye, and carbon disulfide. These chemicals have not only proven dangerous to human health they are also extremely dangerous to marine life when flushed out as wastewater. This process of making bamboo textiles is very similar to the production of viscose – which is made from tree pulp. And while it is often advertised as a green alternative to cotton and other materials – there is a huge chemical impact. Because of the amount of chemical processing required – it is not unfair to describe both viscose/rayon and bamboo textiles as synthetics, or “semi-synthetics” if you will. 95% of bamboo textiles today is bamboo-viscose.

Actually synthetic fibers are usually divided into two groups, one being man-made cellulose fibers like viscose, rayon, and bamboo, and the other being petroleum-derived aka plastic-based textiles. I think it is important to keep in mind that even though the garment is derived from tree-pulp the processing to create cellulose fibers is still considered synthetic. I just wanted to include this distinction as I have seen a lot of people correcting me in previous videos for saying that rayon is synthetic – but by all criteria, it is.

To get an idea of the amount of processing required, check out this visual (Image via Textile School, source: NPTEL)

By the time processing has occurred, the finished result fabric is not really made of bamboo anymore. This is why the Federal Trade Commission (FTC) stated: “When bamboo is processed into rayon, no trace of the original plant is left … If a company claims its product is made with bamboo, it should have reliable scientific evidence to show it’s made with bamboo fiber.”

The Result of High Demand

There are other issues related to the increasing hype of bamboo clothing. One of which is mono-plantations. Because so many consumers are finding the eco (bordering on greenwashing) advertising of bamboo garments as a sustainable alternative to cotton, attractive, more and more bamboo is grown for the sake of textile production. This results in mono-plantations. This is when a large area is devoted to one single crop. We see the same issues with cotton, soy, corn, rice, and many other crops farmed on industrial levels. A mono-culture is extremely bad for bio-diversity because no healthy eco-systems can thrive without bio-diversity. This kills tons of animals, and plants in the surrounding areas, which results in a surplus of other animals. As a result, areas of mono-cultures will have more pests and thus, the farmers will need to use pesticides in order to deliver the products they are paid for. This is in every aspect an ecological nightmare and thus the amazing qualities of pest resistance in bamboo become obsolete when facing unnatural amounts of pests.

also check out: BIOPLASTIC (?) // everything you should know about “compostable” plastics

Is bamboo more sustainable than viscose?

The short and uncomplicated answer that no one is looking for is: yes. Or at least it can be. While heavily processed bamboo is not by any means the most sustainable textile in the world, bamboo is fast-growing and can have some benefits. Viscose is usually made with wood pulp and can be sourced unsustainably from ancient forests. A good option is to look for fibers like both viscose, rayon, lyocell, or bamboo that are processed in a closed-loop system, which is the case for Tencel ( which a company name for their closed-loop lyocell). These systems allow for fewer chemicals used and less water. The Tencel version of bamboo textiles is called ”monocel”.

also check out: HOW IS STREAMING AFFECTING THE PLANET? // the price of being plugged in

Bamboo Claims

“Bamboo clothing is UV-resistant”: any type of tightly-woven material has some level of UV protection effect, so while the claim is true, it is misleading to advertise it as something that is unique to bamboo. Hell, wearing a sack or cardboard box would also be UV resistant.

“Bamboo is anti-bacterial”: although natural bamboo has some anti-bacterial, anti-pest qualities, there is actually no evidence that supports that those qualities are transferred into the textile when the bamboo undergoes chemical processing.

“Our bamboo is OEKO-TEX certified and free from harsh chemicals”: I have seen the oeko-tex standard used as an argument against the criticism of harsh chemicals in bamboo clothing. But it is important to note that oeko-tex ensures that there are no dangerous chemicals left in the clothes once they get to the store so that they are safe for our bodies to wear. It does not cover chemical use throughout the supply chain, so the harsh chemicals are very likely still being used, they are just disposed of before hitting the shelf – which is good news for the consumer’s health, but does not have a positive environmental effect (seriously I need brands to stop using oeko-tex as a sustainability certificate, like right now).

“Bamboo is chemical-free”: while growing bamboo can technically be done without any pesticides or harmful chemicals (however as we have learned, it is hard to actually make sure of that as a consumer, especially when the majority of bamboo is grown in China who has made no restrictions to minimize pesticide use in bamboo production). This is what spokeswoman for the Soil Association (who certifies organic crops) Sarah Compson said about bamboo textiles: “The production of bamboo would fall under our perennial crop standards so, in theory, we could certify the crop – but the problem is the processing. The process needed to break down the bamboo to make the fibers is very similar to that used to make viscose and we’ve yet to see a method that would come anywhere close to complying with our production standards. People always say bamboo is great because it grows so quickly – but so does cotton.” (Kate Carter for The Guardian)

Bamboo clothing does not release microplastic: this one is actually true, semi-synthetic like bamboo textiles, viscose, rayon, etc are still (even when going through significant chemical processing) plant-based. Microplastics are realized from material that are petroleum-based like, polyester, acrylic, and nylon

Nice article. It summarizes many things in a single short article thatI have been researching and reading for past one week.

I am curious, how do you identify & what do you look for while looking for sustainable clothing?

What I have narrowed down to is several certifications (OEKO-TEX, GOTS, AATCC etc.) and the manufacturing process used. Some vendors claim that they use organic chemicals and solvents instead of harmful and toxic chemicals to convert bamboo to viscose and hence the manufacturing process is sustainable. I bought this idea. What do you think of this ?

Just a suggestion – may be you can add a small paragraph at the end as a verdict as to what one should focus on while engaging themselves with sustainable fashion. This will help your readers, at least to avoid people being a victim of greenwashing.

Thank you !!!